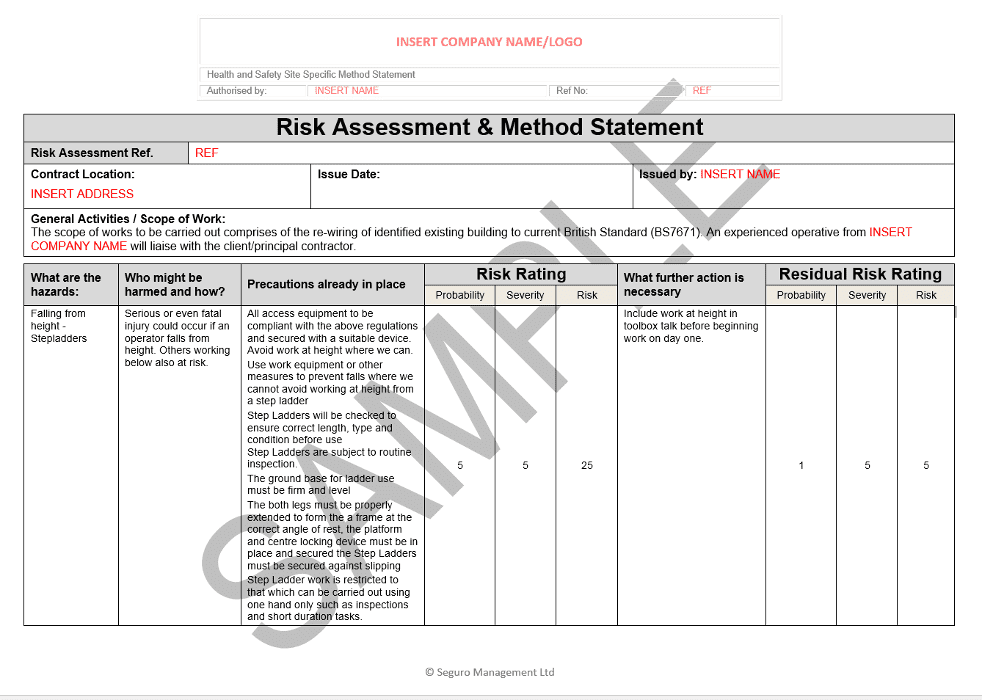

What is a Risk Assessment & Method Statement?

A Risk Assessment & Method Statement is used to describe in a logical sequence exactly how work is to be carried out using safe practices and without risks to health. It should include all the risks previously identified in the risk assessment and the measures needed to control those risks.

How do I complete a risk assessment?

The Good News

We have over 150 comprehensive risk assessment and method statement templates. They have been developed by qualified health and safety professionals. If we dont have one you require, we can write a bespoke one for you.

Our method statement risk assessment document proactively identify, evaluate, and mitigate potential risks.

The documents cover all the appropriate Control Procedures and Hazards for a typical job but can be easily edited to your needs. This is a ready-to-use document that can be implemented in your business straight away.

You can add your brand and adjust the content to fit your site constraints.

Includes:

- 9 to 18 pages of content

- 3,000 to 18,000 words

Additional Information:

- The document covers all the appropriate Hazards and Control Procedures for a typical job

- In “MS Word” format

- Fully editable – include your company logo and details

- The template should be changed to suit the specific job you are performing

Delivery Method:

Available to download instantly once purchased to your email address, ready to start editing to make specific to suit the exact job you are carrying out.

Looking for additional examples of risk assessments and method statements? Explore our extensive range of Risk Assessment Method Statement Templates.

Review some of our RAMS below:

RA1 – Working at Heights

RA2 – Access and Egress

RA3 – Use of Power Tools

RA4 – Working with other Trades

RA5 – Emergency and Fire Evacuation

RA6 – Working within Domestic Properties

RA7 – Personal Safety

RA8 – Lone Working

RA9 – Contact with Biological Hazards, Asbestos etc

RA10 – Use of Wheel Mounted Equipment

RA11 – Working During Non and Poor Daylight Hours

RA12 – Housekeeping & Storage of Equipment & Materials

RA13 – Young Persons

RA14a – Provision of Personal Protective Equipment (PPE)

RA14b – PPE Continued

RA15 – Mobile Tower Scaffolds

RA16 – Use of Ladders

RA17 – Use of Hand Tools

RA18 – Portable Electrical Equipment

RA19 – Cartridge Operating Tools

RA20 – Access Scaffolding

RA21 – Use of Mobile Elevated Working Platforms (MEWPS)

RA22 – Deep Excavations

RA23 – Disc Cutters and Abrasive Wheels

RA24 – Installation of Temporary Electrical Supplies

RA25 – Storage of Materials

RA26 – Company Vehicles

RA27 – Working near Water

RA28 – Work near Power Lines

RA29 – Gas Welding & Cutting Equipment

RA30 – Use of Arc Welding Equipment

RA31 – Electrical Work – Up to 415 Volts

RA32 – Cable Pulling

RA33 – Chasing out for Cable Runs

RA34 – Installation of Cable Trunking and Cable Trays

RA35 – Electrical Testing and Commissioning of Equipment

RA36 – Work in Electrical Workshop

RA37a – Use of Step Ladders

RA37b – Use of Step Ladders Continued

RA38 – Mobile Phones

RA39 – Dismountable Camera

RA40 – Mini Steps

RA41 – Small Dumpers

RA42 – Excavator used for Lifting

RA43 – Slinging of Loads

RA44 – Underground Services

RA45 – Concreting

RA46 – Mobile Cranes

RA47 – Use of Trestles

RA48 – Erection / Use of False Work

RA49 – Laying of Flags and Kerbs

RA50 – Minor Demolition

RA51 – Rendering

RA52 – Use of lifting equipment

RA53 – Asbestos Containing Material

RA54 – Disposal Fluorescent luminaries

RA55 – Disposal Skips

RA56 – Disposal Waste Materials

RA57 – Highly Flammable Liquids Storage & Use

RA58 – Lead & Lead Compounds

RA59 – LPG

RA60 – Excavators

RA61 – Control of Dust

RA62 – Fire on Site

RA63 – Offices, Welfare & Storage

RA64 – Road Transport on Site

RA65 – Working in and around occupied premises

Buy a risk any RAM for £10 each Risk Assessment Method Statement Templates.